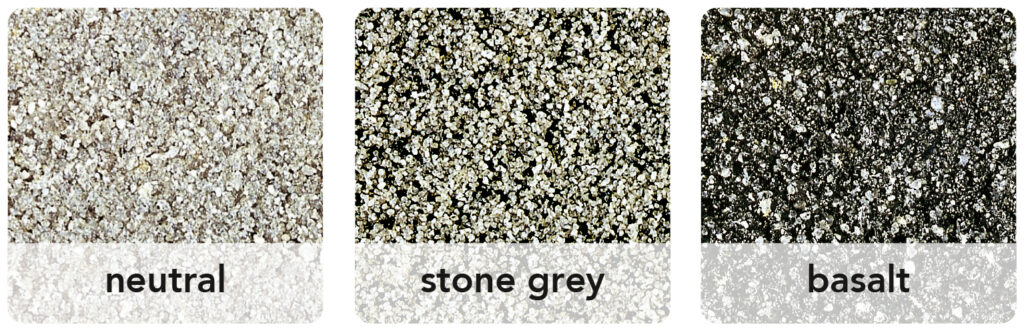

JOINTING SAND NP + D7000 JOINT STRENGTHENER & SURFACE SEALER

Solid & eco-friendly jointing sand solutions

Ideal for Unbonded Construction & Interlocking Pavers

Suitable For Pedestrian & Vehicular Applications

ROMPOX® JOINTING SAND NP + D7000 JOINT STRENGTHENER & SURFACE SEALER is an all-in-one, eco friendly solid jointing sand solution that is manufactured from natural, raw materials, allowing for efficient stormwater management and a significantly stronger, more durable paver joint. Thanks to its simple and quick application, the jointing sand, strengthener & surface sealer combination is ideal for narrow joints, especially with interlocking paving stones on patios and driveways as well as in public spaces. The combination has high strength and viscous elasticity which is particularly advantageous for use on unbonded construction. The sealing properties protect the surface from dirt, oil and corrosion from climate exposure and de-icing salt for up to 5 years.

Note – ROMPOX FUGENSAND must be installed with D7000 and between the temperatures of 10c – 30c

FEATURES

WATCH THE ROMPOX® – JOINTING SAND NP INSTALL VIDEO

HOW-TO-APPLY ROMPOX® – JOINTING SAND NP

1. Pour On

Pour the jointing sand onto the dry surface and mix it with a spade to ensure the best mixing of grainsize.

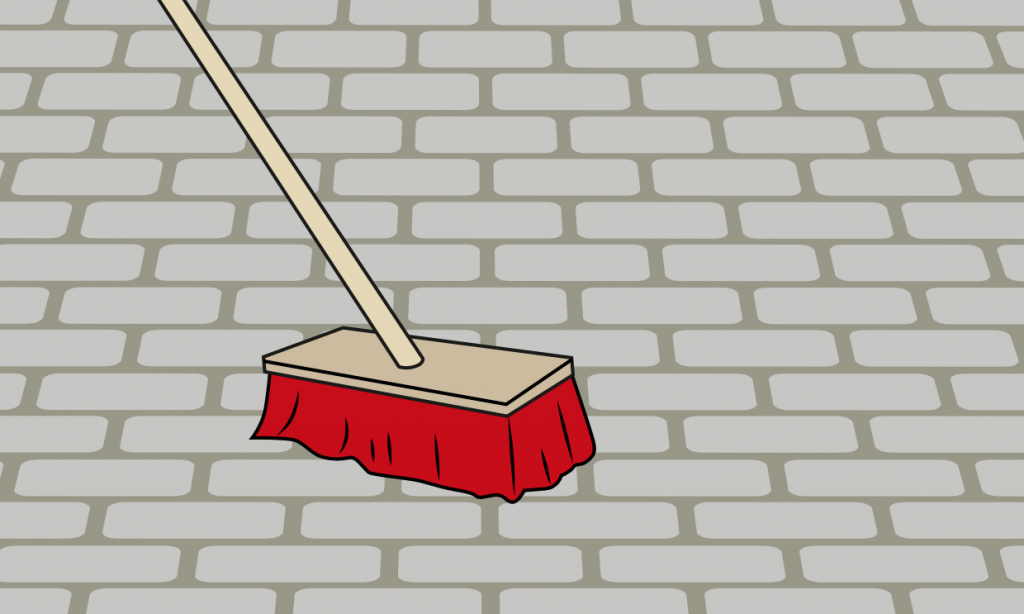

2. Work In

Work ROMEX Fugensand in to the joints using a broom. To achieve comprehensive filling of the joint, always sweep diagonally to the joint and fill the jointing sand up to the top edge of the paving stone or the bevel.

3. Compaction

Use a vibratory plate as long as the surface is suitable for vibratory plates. If necessary use a protective mat.

4. Refill Joints

Refill the joints up to the top edge of the paving stone or the bevel. Sweep the surface carefully using a fine hair broom until no more sand is on the stone surface.

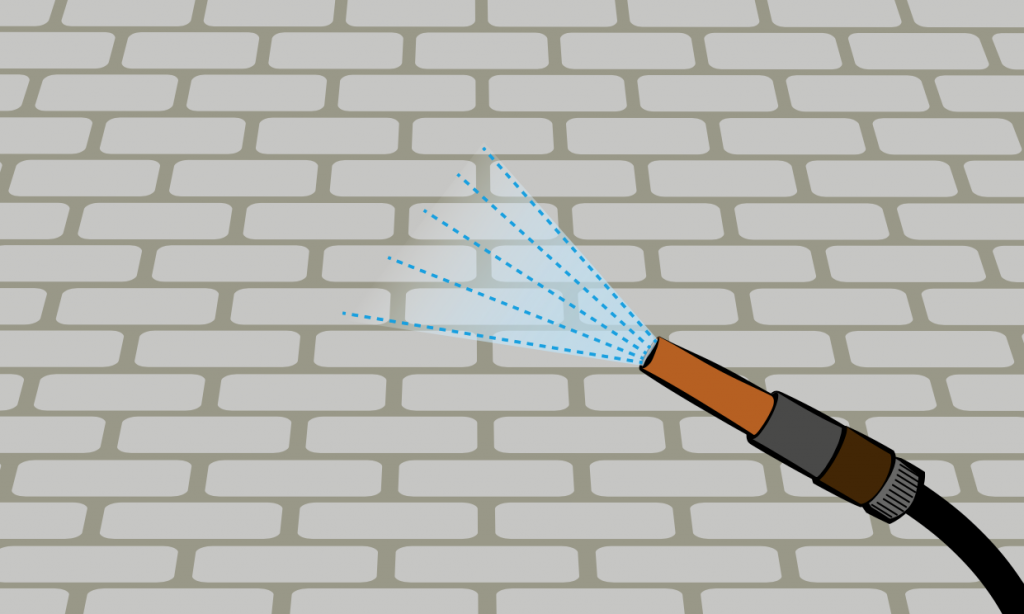

5. Wet Joints

Wet the joints using a spray set to fine mist (Do not use a watering can). The joints should be moistened until they no longer absorb the water. Repeat this process after 1-2 hours.

6. Apply D7000

Lightly mist the surface and apply D7000 Joint Strengthener & Surface Sealer. Thoroughly remove any excess with a double-lipped rubber squeegee.

LEARN MORE ABOUT ROMPOX® – JOINTING SAND NP